The art of resource management

Whether you are an amateur or a professional woodworker, if you are going to build a project of any importance, you will be juggling your resources.

Good management of resources can make the job a pleasure and success; bad resource management can make the job a pain and, at best, difficult.

At worst, it will become impossible to complete.

Resources can be divided into 4 types:

- Time

- Budget

- Expertise

- Equipment

All these elements are interactive and interdependent.

The art of project management is knowing how to balance out these resources to create the most harmonious ensemble that leads to the perfect realisation of your project.

The key word to this art is ‘management’.

Management, not like a tyrant who drives his slaves to work faster to produce more profit, but like an orchestra conductor who must manage his musicians to create the most perfect music.

Objectives and priorities

Whether you are a professional or an amateur, it’s so important to plan out your projects before starting.

Planning will give your project the best chance of success.

Success is a very subjective thing and differs for each person and often each project. It’s defined by objectives and priorities. Getting these clear and in perspective can make or break a project.

If your objective is to make a stair in a limited time, with a limited budget, to move into your new house, the way you organise the project will not be the same as if you want to make the same stair as a woodworking challenge.

Of course, if you are a seasoned woodworker, your objectives and priorities will be evident and instinctive for most projects. However, for more out of the norm projects, it’s always good to take a few minutes to write down a list of objectives and priorities.

To be really effective, objectives need to be clear, precise, and simple. To express a useful objective, you might have to drill down from a general objective to clearer more precise ones.

If you are a professional proposing a project to a customer, it can be useful to write down the customer’s objectives and priorities to be clear about your proposal.

Below is a list of possible objectives and relative priorities.

Note that objectives can often be mixed with desires. A desire can be ditched if a more important objective comes along, but it’s a good idea to write down everything that you want from your project to be able to prioritise correctly.

Note also that it’s important to consider the objectives and desires of all the people involved. This includes family, people using the facility you are building and, of course, if you are a pro, your customer.

Here’s a possible non exhaustive list for an amateur stair builder:

| Objectives and desires | Priority 1 to 5 (1 = top) |

|---|---|

| Challenge of learning stair building | 4 |

| Get cheaper than shop bought | 1 |

| Make in 3 weeks | 1 |

| Be able to say to people that I made my own stair | 5 |

| Enjoy making the whole stair from raw wood | 4 |

| Enjoy making the parts | 2 |

| Enjoy assembling the stair | 2 |

| Use timber I already have | 5 |

Conclusions can be clearly seen from a sorted list:

| Objectives and desires | Priority 1 to 5 (1 = top) |

|---|---|

| Get cheaper than shop bought | 1 |

| Make in 3 weeks | 1 |

| Enjoy making the parts | 2 |

| Enjoy assembling the stair | 2 |

| Enjoy making the whole stair from raw wood | 4 |

| Challenge of learning stair building | 4 |

| Be able to say to people that I made my own stair | 5 |

| Use timber I already have | 5 |

From the second ordered list, it can be seen that the important things to keep in mind are price and time orientated:

- Get cheaper than shop bought

- Make in 3 weeks

After this comes the enjoyment of building the parts and assembling.

And last on the list will be making the whole stair from raw wood, the learning element, being able to say to people that they have made their own stair, and using timber that they already have in stock.

A good compromise for this amateur would be to design a simple stair and buy the timber in pre-cut sections ready to make the parts.

This will minimise the construction time and cost less than a shop bought stair, while still having the pleasure of making the parts and assembling.

Using existing timber and making the stair completely from raw wood may have to be ditched, but the challenge of learning how to build a stair and the pride of having made their own stair remain.

If this person decides to build a complex stair from the timber they have at hand, perhaps so that people will admire their skills, they are likely to find themselves in trouble as costs mount and timescales get stretched.

Exactly what they didn’t want.

For a professional, working through objectives and desires can make a big difference in how you approach a customer.

A clear objectives analysis can make the difference between getting an order or loosing it, between making a profit or a loss, and between having a satisfied or unhappy customer.

Proposing a project that best fits your customer’s desires and constraints will certainly set you apart from the competition and is more likely to result in a satisfied customer.

Proposing an offer that best fits your objectives and constraints will give you more chance of the job being profitable for you.

Note that profitable is not necessarily only financial, but can also be job or creative satisfaction, or a marketing strategy to showcase your work with an influential client, or to try out new equipment or workshop organisation.

If you are a professional preparing a proposal, note down the client’s objectives and then your objectives.

The list might look like this one, in this case for a multi media cabinet project:

| Objectives and desires | Priority 1 to 5 (1 = top) |

|---|---|

| Customer objectives | |

| Install before Christmas | 1 |

| Fit the 1m20 x 50cm space in the front room | 1 |

| Hide television | 1 |

| Be a computer and printer workstation | 3 |

| Hide DVD player | 1 |

| Organise 100 DVDs | 4 |

| Fit a £3000 budget | 2 |

| Use the unit in another house if I move | 4 |

| Fit in a modern room design | 1 |

| My objectives | |

| High quality & long lasting | 1 |

| Manufacture as cheaply as possible | 2 |

| Use Blum hardware | 1 |

| Make a spectacular cabinet so the customer will show off our work | 3 |

| Finish the job within one month | 1 |

| Use cabinet to learn PolyBoard software | 2 |

| Use job to teach apprentice how to run the CNC | 4 |

| Try our new spray paint room | 5 |

| Try our new edging before machining technique | 1 |

Here’s the sorted list:

| Objectives and desires | Priority 1 to 5 (1 = top) |

|---|---|

| Customer objectives | |

| Install before Christmas | 1 |

| Fit the 1m20 x 50cm space in the front room | 1 |

| Hide television | 1 |

| Hide DVD player | 1 |

| Fit in a modern room design | 1 |

| Fit a £3000 budget | 2 |

| Be a computer and printer workstation | 3 |

| Use the unit in another house if I move | 4 |

| Organise 100 DVDs | 4 |

| My objectives | |

| High quality & long lasting | 1 |

| Use Blum hardware | 1 |

| Finish the job within one month | 1 |

| Try our new edging before machining technique | 1 |

| Use cabinet to learn PolyBoard software | 2 |

| Manufacture as cheaply as possible | 2 |

| Make a spectacular cabinet so the customer will show off our work | 3 |

| Use job to teach apprentice how to run the CNC | 4 |

| Try our new spray paint room | 5 |

The budget seems a little bit flexible, but if costs need to be reduced, DVD storage space first and then the computer and printer workstation could be removed from the project.

Incorporating the TV and DVD are far more important however.

From the ‘My objectives’ list, quality and manufacturing time are high priority, whereas spending extra time teaching the apprentice CNC might have to wait for another job that’s less tight on time.

The same might be the case for going the extra mile and spending more time to make a showcase piece.

Keeping your objectives and priorities in mind will help you choose the right resources to complete your project.

Time considerations

Time is a strange beast.

A professional must minimise manufacturing time to reduce costs and increase margins. Whereas it’s difficult to enjoy and take pleasure in doing something if you are stressed out because of lack of time.

So what to do if you want to make money and enjoy your craft?

The secret is in time management.

Most amateurs don’t worry about time management because, as a hobbyist, the priority is to enjoy doing the job.

This is OK for most projects, but be careful if you are doing bigger projects like kitchens, stairs, etc. that have to be finished in a reasonable timeframe. It can be really difficult to be weeks from finishing a stair when you have to move into your new house tomorrow.

Remember that for larger projects, time and lack of time can be a real handicap to enjoying the making of it. For these projects, it’s always a good idea to try and estimate the time you’ll need to do each operation required to complete your project… and then double it.

If after this you lack time, don’t hesitate in sub-contracting parts of your project, for example by:

- Buying pre-planed wood

- Outsourcing the machining

- Buying or renting a tool or machine to make the job faster

For professionals, effective time management is a must for a successful business. It can make the difference between the life or death of a business, and at the very least of making a good living versus continually struggling to make ends meet.

Define your objectives

How you manage your time will depend on your objectives.

If you’re in business to make money as your first priority, the road is simple, at least on the production side of things.

You have to create demand for your products and produce them as fast and as cheaply as possible.

On the other hand, if you are in business because you enjoy your craft, and also need to make money of course, things can become more complicated.

Defining clear objectives and prioritising will enable you to use your time effectively and can often help make your business run smoother and, in the end, make it more enjoyable and more profitable.

To estimate time for a project, you must break it down into manageable portions. Keeping your project objectives list in mind, make a list of each task and write down the time needed to accomplish it.

Here’s an example table for estimating and managing the time, in this case when building a quarter turn stair:

| Task | Outsource time estimate | In-house real time | Outsource real time | Est. and real difference | Observations |

|---|---|---|---|---|---|

| Pre-design customer consultation | Starting from rough cut timber | ||||

| Taking on site sizes | |||||

| Design, drafting and set up | |||||

| Printing cutting list | |||||

| Printing plans | |||||

| Printing templates | |||||

| Researching wood and materials | |||||

| Buying wood | |||||

| Transport and delivery | |||||

| Parts | |||||

| Steps | |||||

| Rough cutting | |||||

| Planing | |||||

| Jointing | |||||

| Flushing | |||||

| Marking out | |||||

| Final cut | |||||

| Detailing | |||||

| Adjusting | |||||

| Stringers | |||||

| Rough cutting | |||||

| Planing | |||||

| Jointing | |||||

| Flushing | |||||

| Marking out | |||||

| etc | |||||

| Total cost |

Note that in the table, there is a time column for outsourcing. This is not just a cost. Outsourcing can sometimes take up more of your time than doing it yourself.

If you are a professional, you should fill this table out for every job or job type. If you have employees, tracking production time is a must for any successful company.

To play with different options, use a spreadsheet and copy the table several times. This way, it’s quick to see the impact on time of, for instance, sub-contracting an operation or doing in-house.

There are also columns for real time, which should be used after the project is complete to review how it went.

Scope for improvements

Complete the in-house or outsource box, whichever was used, then work out the difference between your estimates and the reality, and of course, consider ways to improve the process for next time.

This will quickly show where you can gain time:

- Is something taking longer than it should?

- Are there faster alternatives to achieve the same goals?

- Is it better to outsource or do in-house, or indeed to delegate within your own team?

- Can different tools, software or training speed things up?

And of course, successful time management should give you more time, enabling you to directly influence all other resources.

More time will enable you to:

- Reduce budgets and increase profits

- Learn new techniques and acquire expertise

- Set up and organise new working methods, tools and materials to make your work easier and more pleasurable

Budget

In today’s world, time is money.

A terrible equation that makes for an inhuman world.

Lucky for us humans, this is not a mathematical equation, and as anyone who enjoys creative craftwork knows, passionate involvement gives satisfaction and rewards that are not measurable in money.

This said of course, whether you are a professional or amateur, budget is an important part of any project and will determine how you organise your other resources.

Knowing how much your project is going to cost is an important first step to success.

If you are an amateur, you don’t have to count your time in a budget, but professionals of course must count an hourly rate in the total cost of a project by combining the two tables, our time table of earlier and the budget table below.

Outsource vs in-house

For an amateur, outsourcing will incur the cost of the outsourcer, whereas for a professional, outsourcing will also incur the time spent finding a sub-contractor, training the sub-contractor, and perhaps transport of parts to and from the sub-contractor.

If you are thinking of weighing up the pros and cons of several options, copy your spreadsheet and modify the necessary items.

For instance, 2 different spreadsheets can show at a glance the impact of using laminated boards against starting from rough timber.

Increasing the budget can decrease the time required by allowing outsourcing, buying tools and employing experts or carrying out training to do specific tasks.

Please note on the table below to budget for no more than 10% of the costs of new tools against this project. This is to quite rightly spread the costs of the investment across multiple projects.

| Task | In-house budget estimate | Outsource budget estimate | In-house real cost | Outsource real cost | Est. and real difference | Observations |

|---|---|---|---|---|---|---|

| Pre-design customer consultation | Starting from rough cut timber | |||||

| Taking on site sizes | ||||||

| Design, drafting and set up | ||||||

| Printing cutting list | ||||||

| Printing plans | ||||||

| Printing templates | ||||||

| Researching wood and materials | ||||||

| Buying wood | ||||||

| Transport and delivery | ||||||

| Parts | ||||||

| Steps | ||||||

| Rough cutting | ||||||

| Planing | ||||||

| etc. | ||||||

| Hardware | ||||||

| Glue | ||||||

| Rail bolts | ||||||

| Varnish | ||||||

| etc. | ||||||

| Extra tooling | ||||||

| (Include 10% of costs only) | ||||||

| New router | ||||||

| Dowel jig | ||||||

| Cross cut saw | ||||||

| Total cost |

Minimum expertise

Every job will require a minimum level of expertise.

The higher your expertise, the less time and money that will be needed to complete the project.

Expertise is the capacity to analyse and create solutions for real life problems.

Knowledge and experience

Expertise comprises knowledge and experience.

Knowledge is something you have learned and know how to do.

Experience will enable you to master what you know and create solutions.

Experience will require much more time to acquire.

Knowledge can be acquired fairly quickly. Read a book, have a look at a YouTube video, and you’ll know how to do it.

Knowledge is like building blocks of information that can be strung together to create solutions for different problems and circumstances.

Experience, on the other hand, allows one to sift through what one knows and choose the chain of elements you ‘know’ to become a real usable solution.

Minimum requirements

For woodworking projects that you are not entirely sure of, it’s important to have the know-how.

You can look through books, read online guides and look at videos. With a little experience, you will then be able to apply most of this information to build simple projects.

But if your project is complex or just unusual and you don’t have the experience, you will invariably find yourself at some point blocked and asking what’s the best way to go about building it.

That’s when you’ll find that the experience of others is invaluable.

Learning from the experience of others can speed up the project build time by a multiple of 10 or more!

If you’re not sure what knowledge and experience you need for a specific job, below is an example table that you can use to see how your actual level of expertise might impact the time you need to build your project.

As well as amateur woodworking examples, we use the scenario of a professional who will be buying CNC equipment to complete a job…

| Knowledge required | Knowledge 1 to 5 | Expertise 1 to 5 | How to acquire | Time to add to project | Money to add to project |

|---|---|---|---|---|---|

| Amateur cabinets | |||||

| Use design software | |||||

| Read plans | |||||

| Cut with circular saw | |||||

| Drill holes | |||||

| Use dowel jig | |||||

| etc. | |||||

| Amateur stairs | |||||

| Use design software | |||||

| Read plans | |||||

| Cut with circular saw | |||||

| Use chisels | |||||

| Use hand drill | |||||

| Use router | |||||

| Use sander | |||||

| Assemble boards | |||||

| etc. | |||||

| Pro cabinetry with CNC | |||||

| (Experienced cabinet maker) | |||||

| Organise workflow | |||||

| Use design software | |||||

| Use cutting or nesting optimisation software | |||||

| Run CNC programmes | |||||

| etc. |

Tool requirements

Minimum tool requirements must also be determined according to your objectives and balanced out with other resources.

Tools will enable you to minimise time but might eat away your budget if you have to buy new tools.

In some cases, you’ll also have to acquire the expertise needed to use your new tools.

Besides basic hand tools that every woodworker should have, here is a non exhaustive list of the different power tools that you will need for all but the simplest of jobs.

| Tool requirements for | Minimum | Optional | Cost |

|---|---|---|---|

| Amateur cabinet maker | Drill | £20 – £50 | |

| Dowel jig | £10 – £100 | ||

| Circular saw | £40 – £150 | ||

| Jig saw | £30 – £150 | ||

| Drill press | £100 – £400 | ||

| Biscuit jointer | £50 – £200 | ||

| Table saw | £100 – £400 | ||

| Amateur stair maker | The above + | ||

| Router | £50 – £200 | ||

| Belt sander | £50 – £200 | ||

| Orbital sander | £50 – £200 | ||

| Drum sander | £1000 – £3000 | ||

| Professional cabinet maker | The above + | Prices so variable not provided | |

| Table saw | |||

| Drill press | |||

| Jointer | |||

| Panel saw | |||

| CNC router | |||

| Edge bander | |||

| Professional stair maker | The above + | ||

| Band saw | |||

| Thickness planer | |||

| Spindle moulder | |||

| Portable spindle moulder |

How Wood Designer can help you manage your resources

Supporting professional workshops

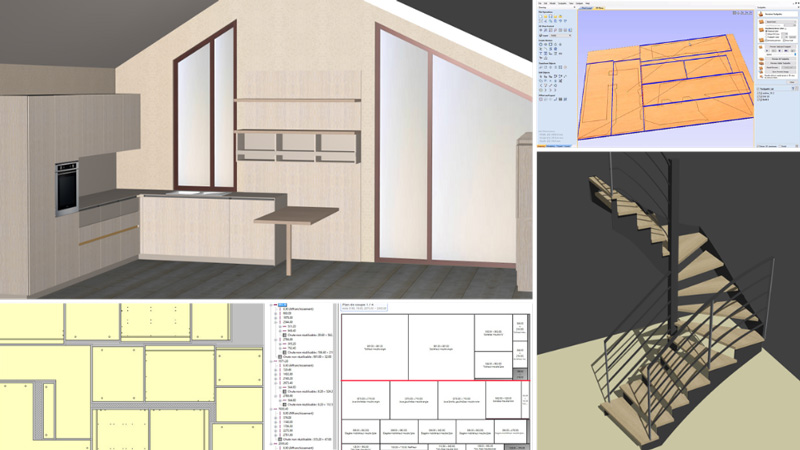

If you feel that time is becoming increasingly scarce, and you’re drawing your designs by hand or with a traditional CAD package, please take a look at our design to manufacturing software.

PolyBoard for cabinets, and StairDesigner for stairs.

The software have been created for professionals, so they’re powerful and flexible enough to cater for lots of different construction methods.

At the same time, they’re simple enough that you won’t need a dedicated technician to use them. And because they’re parametric, they’re very fast and error free… Resize your overall project dimensions and all parts are automatically updated.

You also have instant access to:

- Cutting lists

- Part by part plans

- 1:1 templates (for StairDesigner)

- CNC files

- Cost and material reports

- 3D renders

Optionally, add in OptiCut or OptiNest to automatically optimise the cutting list, save on materials and speed up production even more.

If you have a steady volume of orders, it might be time to invest in a CNC machine. Our software will integrate will all CNCs, but it’s not always easy deciding on the right configuration.

Please consider talking to one of our technical experts, they have worked with a huge range of workshops using different set ups, and would be happy to discuss the best options for your business.

Amateur woodworkers can still use our pro software

Although our software have been created for professionals, we have a cut list and processing service which allows you to create your design with the free version of PolyBoard or StairDesigner, and receive your manufacturing output to build it.

Please check out our CabinetFile and StairFile services for more information.

These services include access to our exclusive Wood Designer forum, where you can discuss your project with our team of woodworkers with all their expert knowledge and experience.

We’ve got lots of ways to help you focus on the parts of your project you enjoy the most.

Conclusion

This guide is just an overview of how to manage resources in a small workshop.

Most amateurs and small to medium businesses manage resources ‘on the fly’ and rarely take the time to sit down and reflect on objectives and resources.

This is a pity, even if most amateur and business activity can be managed instinctively. A more systematic approach to resource management can make a lot of difference at certain key moments:

- When bidding for unusual jobs

- When starting to build unusual projects

- When an important investment decision has to be made

In general, for a small to medium business, a regular and systematic analysis of objectives and resources can make running a profitable business a lot easier, less stressful, and much more pleasurable.

Please get in touch if you would like to discuss the best software or service for your needs. We’re very happy to provide advice outside of our specific product range where we can too.

Happy woodworking.