OptiCut 6 is now available and features a range of powerful new capabilities you’ve asked us for to cut your parts even more effectively.

To help you access these new features we’ve got a package of great offers, whether you’re upgrading or want to add OptiCut to your workshop for the first time.

If you’re already using Polyboard, these new features are even more powerful.

See below for update details, pricing and some great launch discounts

New features

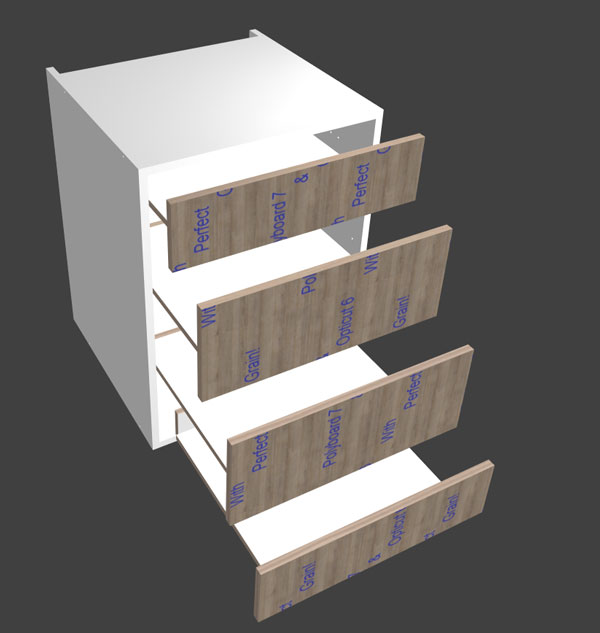

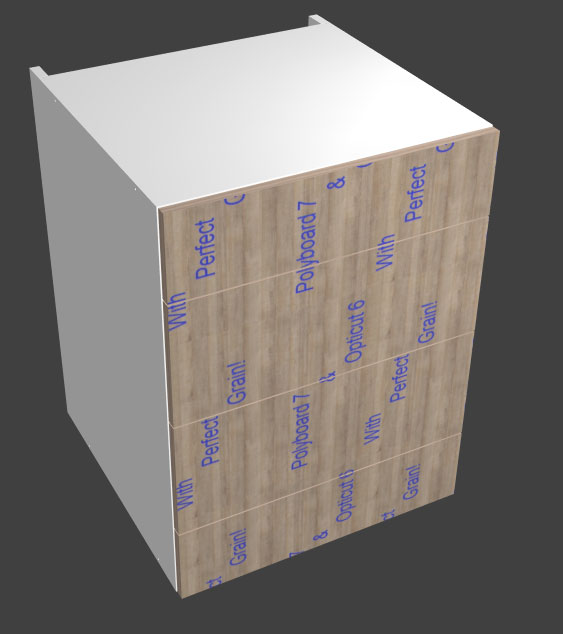

Perfect grain has arrived!

We’ve had many requests for true grain management to take OptiCut to the next level of cutting optimisation. We’re very happy to be able to share that with you now.

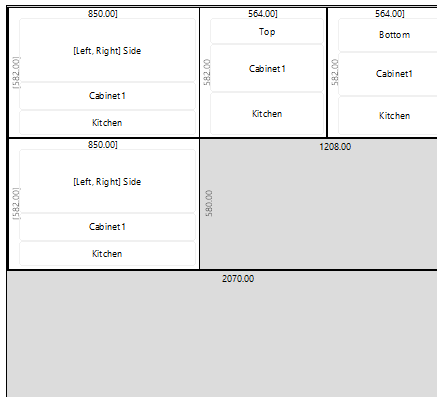

Ensure the grain of your material flows perfectly across multiple adjacent parts of a cabinet (such as your drawer and door facades) or across multiple cabinets. No more manual selection and grouping of parts on your sheet material.

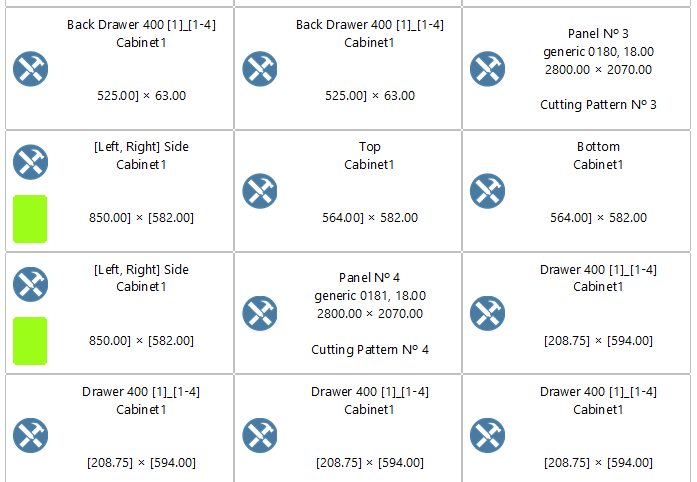

Polyboard to OptiCut auto grain management

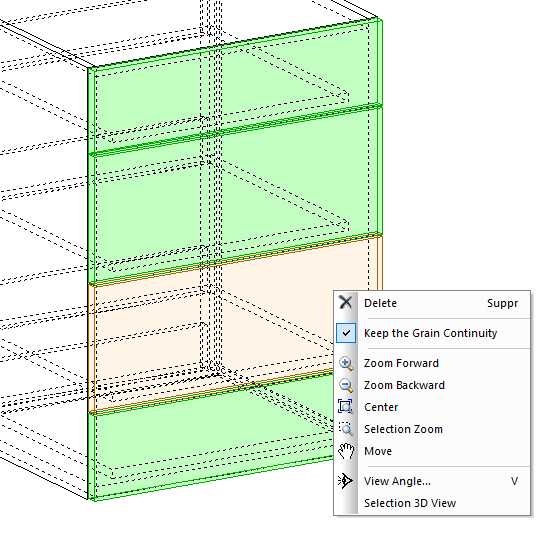

This feature works best in tandem with Polyboard (version 7 onwards), our cabinet design software.

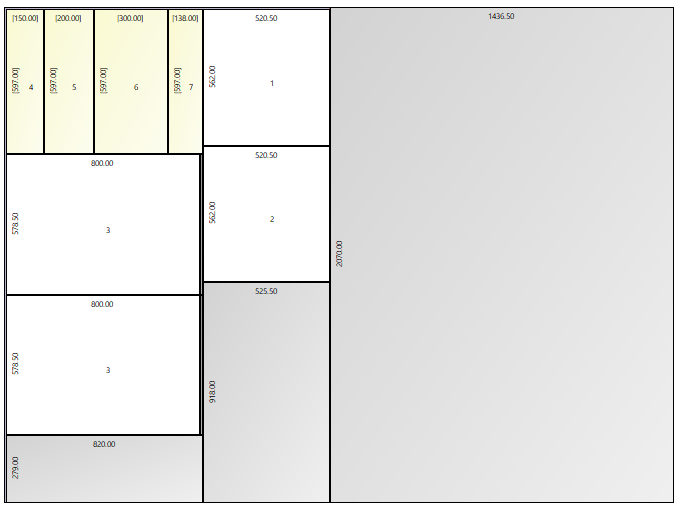

The sequence of images below shows the process for a cabinet, first setting the grain continuity parameter in Polyboard to instruct OptiCut to group the parts correctly.

This data is included in the full cut list information OptiCut uses to output ready for manufacture cutting maps for your manual or CNC saw.

Grain management within OptiCut alone

If you don’t use Polyboard with OptiCut, you can still select and group a range of parts at OptiCut’s cutting list level for application of this grain feature. Grouping across multiple cabinets is also performed inside OptiCut.

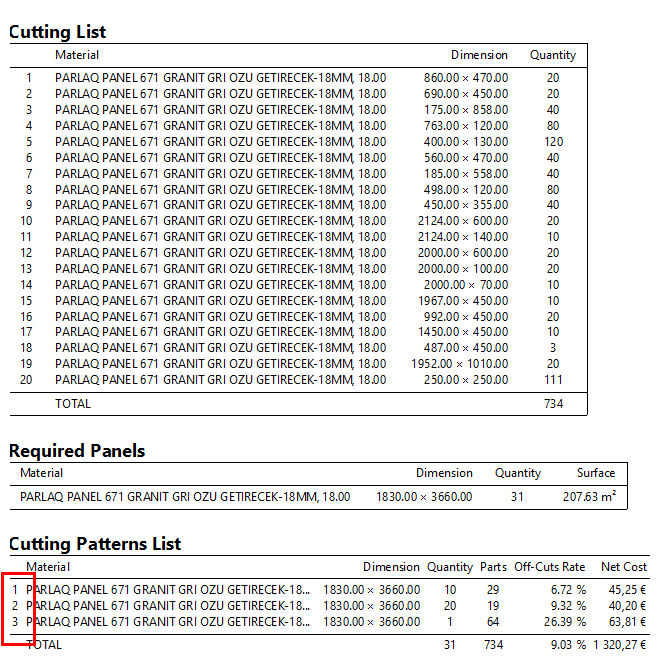

Minimise the number of cutting patterns

OptiCut’s new optimisation engine reduces the total number of cutting patterns for your projects in a big way.

By a cutting pattern we mean a specific and unique cutting map. If you can reduce the number of cutting patterns in a project, the complexity of manufacture is reduced.

It’s quicker to cut and apply the labels if you’re working with the same cutting map multiple times. If you are cutting manually you can also stack multiple boards and cut them together.

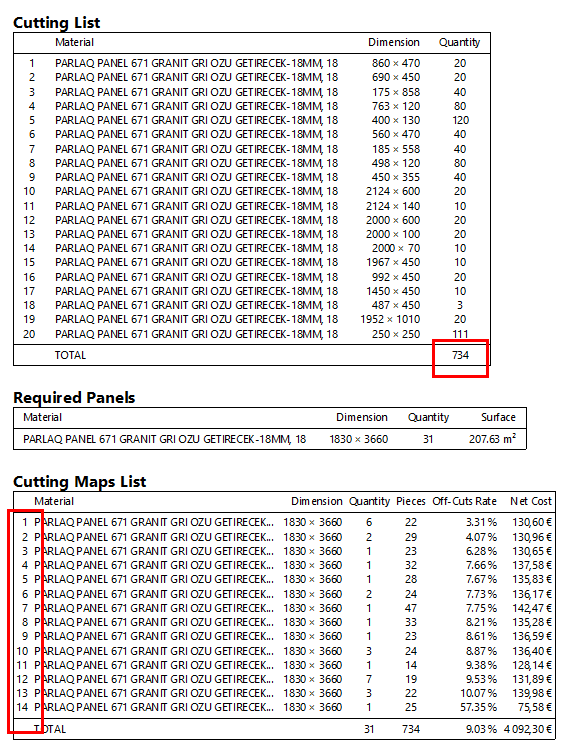

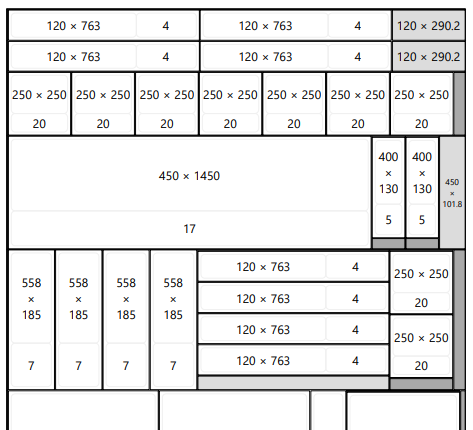

The project shown below has a cut list of 734 parts. OptiCut’s updated algorithm results in a reduction of cutting patterns from:

14 down to only 3

That’s a huge gain in the simplicity of the cutting process.

Plus lots more features including…

Colour coded labels + custom logos

Colour code each cutting list line, fully printable on your labels.

Enables even faster sorting of the parts by cabinet, material or machining operation as defined at the cutting list level.

And you can now add your company logo to labels too.

Print multiple references on your cutting maps

Instead of having to choose only a single reference to show on your printable cutting maps, you can now select multiple references.

Grouping of similar parts

Further enhancements to OptiCut’s optimisation algorithm to group similar parts together for simpler and more efficient cutting.

New configurable interface

Custom management of the Properties window, Tool Tips and more.

Pricing and upgrade details

For new users of OptiCut

Save on material waste, speed up your manufacturing workflow and start using OptiCut as your stand alone cutting optimisation solution, or combine with Polyboard to seamlessly take your cut list and output an optimised cutting map for your saw, and now with full grain management.

Our standard retail prices are shown here

More details on OptiCut are available here

Contact us to discuss your requirements and to request a demonstration of the software.

Upgrade details if you are already using OptiCut

If you already own OptiCut, the upgrade price is linked to when you purchased the previous version.

Special discounts apply if you wish to upgrade across versions as well, for example from OptiCut 200 release 5 to OptiCut Pro release 6.

How to lock in the best discount

The sooner you order your upgrade, the better the discount.

If you’d like to benefit from OptiCut’s new features, please contact us for a quote as soon as possible.

I’m the the new user how can I get opticut?

Hi Mirjam

Thank you for your comment!

Register for free first of all.

Once you’ve done that you’ll be able to download OptiCut.

We also offer online demonstrations of of the software if you’re thinking about using OptiCut for your business, please contact us here if you would like to discuss that.

Have a lovely day!