Wood Designer forum

Working area aswell as machine parameters.|Forum|WOOD DESIGNER

September 2, 2022

Offline

OfflineAlex said

Hi,I have feedback from developpement team’s, the documentation of Maestro (Maestro Scripting language) don’t have instruction to implement this option into PolyBoard,

I suggest that you contact SCM to find out about the available option, as they are generally quicker to reply to their customers than to reply to us.

Cheers, Alex

Hello Alex.

Alright. Thank you for looking into it and for your time

January 20, 2017

Offline

OfflineHi,

I have feedback from developpement team’s, the documentation of Maestro (Maestro Scripting language) don’t have instruction to implement this option into PolyBoard,

I suggest that you contact SCM to find out about the available option, as they are generally quicker to reply to their customers than to reply to us.

Cheers, Alex

September 2, 2022

Offline

OfflineAlex said

If I well understand you want to change this parameters at 30 to 300?Cheers, Alex

no but yes in a sense. if that parameter is increased to 300 then it’ll be added to every single milling. what im wondering about if its possible to have a parameter on the tool in SD so that the tool in maestro has its safety quote to be changed (same as in the picture attached).

September 2, 2022

Offline

OfflineHello Alex.

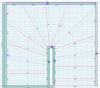

well this issue is always when there’s a hard incline cut (ish from about 30 degrees to close 85 ish degrees). so if we have a fixed straight step then comes a angled step afterwards. The first riser in the starting of the turning of steps (and last when its going back to a straight step). ( the picture is a example. step 2, 7 and 11 would be the major problem causers while the others arent as bad, but can still cuase issues). risers with a easy cut are not a problem, since the machine dosent have to angle as much. ( step 5 and 9 forexample )

When you say PP parameters, what is it your refering to ?

January 20, 2017

Offline

OfflineHi there,

Can you provide us project with this issue? Your PP parameters?

and a screenshot of Maestro’s configuration?

Kind regards, Alex

September 2, 2022

Offline

OfflineAlex said

Anything is possible, but it’s also a question of cost, so I can ask the development team for an addition which would then be subject to quotation.But I’d be looking more at Lead IN and Lead OUT.

This allows the tool to be relieved at the end of the sawing process.

I’ll let you try it out, tell me if it’s suitable, and then I’ll make the request to the development team.

Cheers, Alex

Hello Alex.

Thank you for the suggestion. I tried fiddeling around with the lead in/out, but as i can see with the parameters when its regarding a inclined cut, they can only do liniear entry whiche as far as i can understand is a straight y entry/exit adjustment. and saddly what i need is a z adjustment, so that it can come up in height befor traversing acroos the piece. in the lead in/out it has longer time to get in the z height, but the cnc makes it so that the further it has to travel, the slower it turns the head (b and c axis). so it becomes a problem either way.

Could you ask for that quotation ? then i can give it to my boss for consideration.

January 20, 2017

Offline

OfflineAnything is possible, but it’s also a question of cost, so I can ask the development team for an addition which would then be subject to quotation.

But I’d be looking more at Lead IN and Lead OUT.

This allows the tool to be relieved at the end of the sawing process.

I’ll let you try it out, tell me if it’s suitable, and then I’ll make the request to the development team.

Cheers, Alex

1 Guest(s)

Home

Home