- Home

- Help Centre

- PolyBoard tutorials

- CNC integration

- Point to point versus nesting CNC machines

- Home

- Help Centre

- StairDesigner tutorials

- CNC integration

- Point to point versus nesting CNC machines

Point to point versus nesting CNC machines

Which is going to be best for your workshop, and recommended software configurations for each.

PolyBoard acts as the design tool and starting point for both configurations but the production process is different.

(we are focusing here on furniture manufacture using PolyBoard with your CNC, but the same set up applies for stair design with StairDesigner)

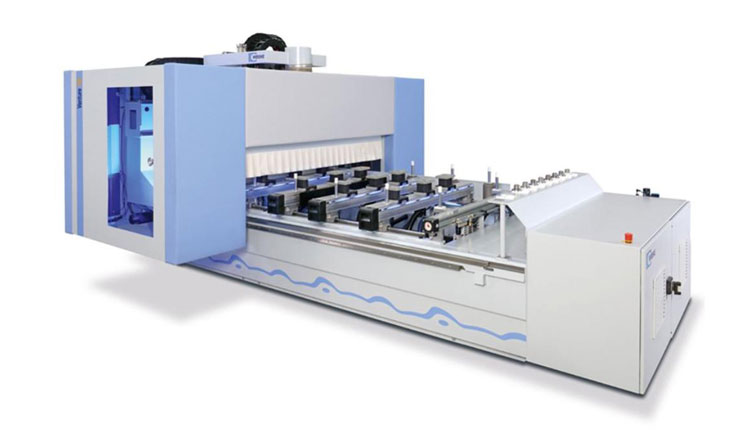

1. Point to point manufacturing

(also called pod and rail or part by part manufacturing)

- PolyBoard will output the drawing of each part

- You then take a panel saw and from a sheet cut out each part

- Each part is put on the CNC one at a time

- Vacuum pods hold the part in place

- The machine turns around the part adding the machining for your panel fittings, drawer sliders, hinges and so on

PolyBoard has specific post processors for a range of popular brands of CNC. PolyBoard outputs all the machining details in the CAM software’s native file format for super fast processing and generation of the machine code to run your CNC.

There are 100s of types of CNCs so PolyBoard may not have have a post processor for your specific brand. In this case, we use PolyBoard’s DXF post processor to output DXF files into your CAM software.

Almost all CAM software solutions accept DXF files and this is the most common CNC configuration we see. In fact, CAM software like VCarve now offers an integration which is comparable in speed to the brand specific post processors we discussed above.

Click here to find a list of PolyBoard post processors and CNC integrations.

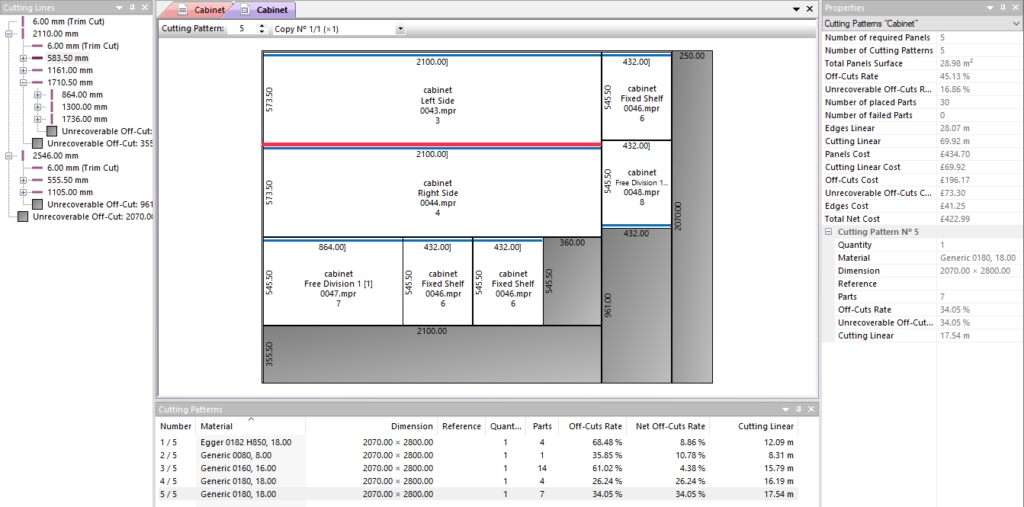

Want to optimise your cutting list too?

If you are using a point to point configuration, you will always need to cut your parts out first.

You can manually cut the parts from the sheet material, but it is more efficient in time and money to use a cutting optimisation solution. PolyBoard’s cut list can be sent seamlessly to OptiCut to produce an optimised cutting map. This shows the position and sequence of the cuts to minimise time and waste.

The panel saw can be replaced by a CNC saw. To run a CNC saw, PolyBoard’s cut list is sent to OptiCut Pro PP which outputs the code to directly run the saw’s complete cutting sequence. All you have to do is load up the panel.

OptiCut offers a large range of post processors for all major saws.

Click here for details on OptiCut

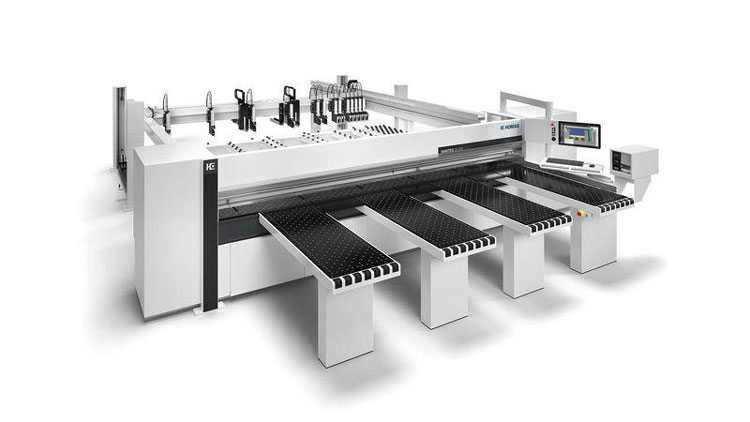

2. Nested manufacturing

- You do not need a panel or CNC saw

- A nesting machine will have a vacuum bed or table to hold the panel in place

- You put the whole panel on the CNC machine

- The machine cuts each part out of the panel and applies all the machining to each part

PolyBoard still outputs a file for each part. But these files are first put through dedicated nesting software (like our OptiNest solution) or directly into CAM software that has the ability to nest the parts onto the sheet size.

Once nested on the sheet, your CAM software produces a machine file to tell the CNC what to do with that drawing, so how to cut out each part and how to machine each part (including which tool to use and when).

So the minimum configuration you need is PolyBoard with nesting CAM software. Again, PolyBoard comes with a range of brand specific and generic DXF post processors to link up with virtually any CNC.

Again, click here to find a list of PolyBoard post processors and CNC integrations.

What if my CAM software doesn’t offer nesting?

VCarve offers basic nesting as do other CAM solutions. Some packages like Alphacam come with an excellent nesting module.

Depending on your CAM software, or if you want to add a complete nesting solution, please take a look at our OptiNest software. This does a very good optimisation that can be fine tuned to your exact specfications (for example balancing cut time vs material waste) as well as printing labels of each part and managing your stock of panels and usable off-cuts.

Click here for details on OptiNest

Which is better, point to point or nesting?

Point to point advantages

Point to point works well for a high volume workshop producing standard items with a large number of similar parts. The parts can be cut in stacks with a beam saw and all of a single part type machined one after the other using the same machine file.

Point to point requires at least one person full time to cut, organise and machine.

Nesting advantages

Nesting works better for small to medium workshops working in particular on custom projects. It is much faster because you do not need a saw to cut the parts beforehand. Nor do you need to load each part separately onto the machine. Space requirements are also less. Nested parts produce up to 10% less off cuts than cutting optimised parts.

Labour costs are reduced because once a sheet is loaded onto the CNC parts production doesn’t require any personal intervention.

Traditionally the other advantage of point to point was that you could machine on the sides of each part, as required for a classic cam and dowel arrangement for example. However, there is now a good range of hardware available that only requires machining from above.

If you definitely need edge drilling, you can opt for a boring machine to supplement a nesting CNC, this can still allow you to work faster and can come in at a lower price than with a point to point.

Whether you opt for point to point or nesting, PolyBoard’s Quick Design libraries include a range of pre configured set ups for both methods, and a large hardware library ready to go.